products

Pumping systems

Pumping systems

Description

For over 30 years Peroni has been designing and manufacturing complete pumping systems for chemical injection and dosing units, for pumping stations, pipeline testing units, descaling and water press feed packages, injection systems of cement mixtures for ground consolidation.

Peroni offers extensive project engineering and management resources ensuring a wide range of product expertise and providing complete solutions.

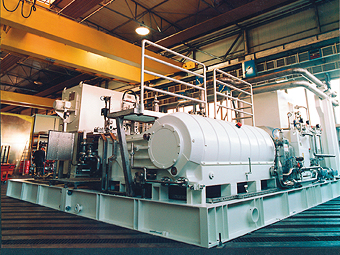

These systems, generally mounted on skid, are designed according to customer specifications and are supplied pre-assembled, wired and tested, ready for installation.

Important engineering activity is also applied to the design of pumping units that recently have become very complex. These units include auxiliary circuits, complex instrumentation and speed control systems required by the nature of the service and they must interface with the plant where the pumping unit has to be installed.

Produced water injection system for offshore installation in the North Sea. Total capacity 190 m3/h, delivery pressure 502 bar, with a total installed power of 3500 kW. The unit is skid mounted and consists of one booster pump and two PSO 190 septuplex pumps electric motor driven with frequency converter control and is complete with all necessary auxiliaries. The unit is designed fully in accordance with API 674 and Norsok standards.

Pumping system installled on an artificial island in the Caspian sea (Kazakhstan) for Methanol injection to wells through adjustable flow rate injection valves.

PTO3/160 pump - 13,5 m3/h - 659 bar

Methanol injection unit for installation on a FPSO in Angola. The unit is skid mounted and consists of one PTO 190 triplex pump with 319 bar delivery pressure and 51 m3/h capacity. The pump is driven by an explosion proof (Atex) diesel engine of 800 kW and the unit is complete with auxiliary circuits, diesel tank and instrumentation.