Known globally for their quality and reliability, Peroni Pompe industrial pumps stand out due to their distinct design attributes.

Peroni Pompe pumps are designed to maintain comparatively low operating speeds, typically not exceeding 300-400 RPM. This design reduces the cycle count on critical hydraulic end components like valves and seals, thereby significantly enhancing their reliability and longevity.

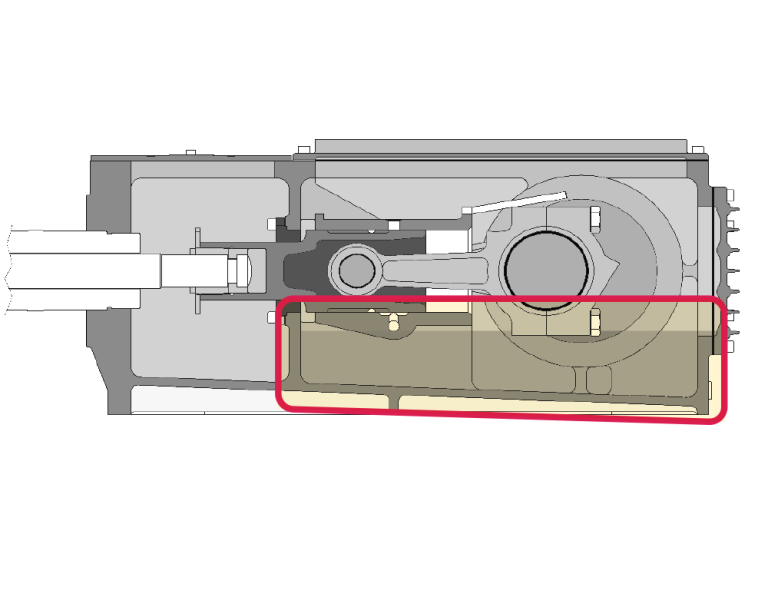

A wide range of Peroni Pompe pumps are lubricated through a unique splash and flood system. The lower part of the crankshaft is designed to dip into the oil reservoir, and splashes oil to the other moving components of the crankshaft ensuring a long life of components. Pumps equipped with this system do not require any external equipment for forced lubrication nor to cool down the lubricating oil.

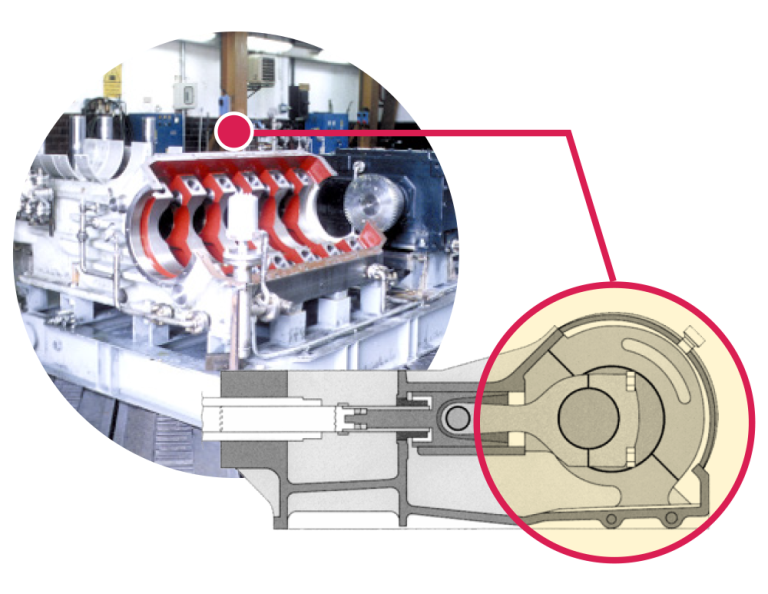

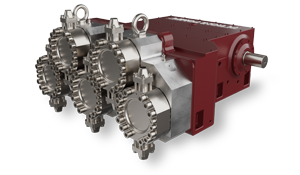

Large pumps exceeding 1100 kW power incorporate a continuous shaft support for uncompromising safety levels. This support is achieved through individual sleeve bearings for each plunger, resulting in decreased stress levels that intrinsecally safeguard against shaft failure.

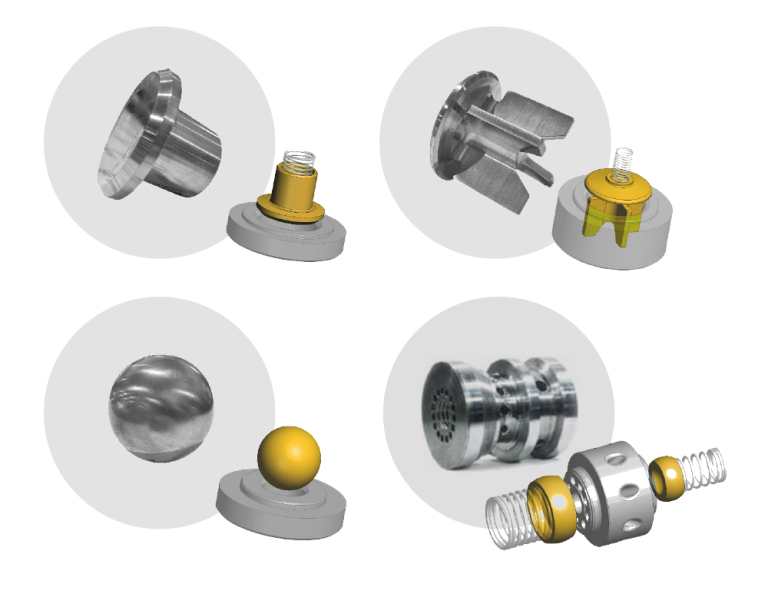

Peroni Pompe offers an extensive selection of valves and manifolds tailored to address the demands of the most rigorous pumping applications. Even extreme conditions such as ultra-high pressures up to 4000 bar, elevated temperatures, very large flow rates, and fluids with solids, abrasive, corrosive, or high viscosity properties pose no issue to our pumps. Over its century-long operation, Peroni Pompe has acquired a comprehensive portfolio of technical solutions for every challenge.

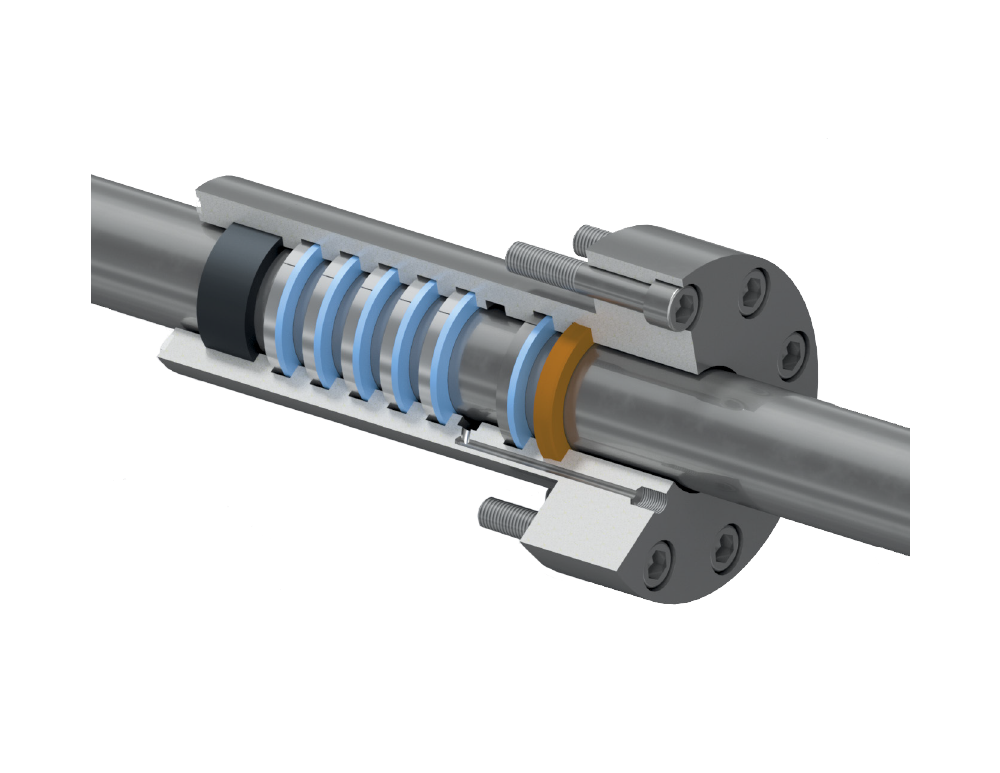

Peroni Pompe can provide the right sealing technology for any specific high pressure challenge! Traditional braided packing ring technology has been perfected by Peroni Pompe through the integration of a variety of auxiliaries including injection, flushing, and barriers, tailored to each specific condition. Moreover, Peroni Pompe offers its unique Dedalo® seal, a singular solution offering zero-leak and maintenance-free operation under continuous duty. The exclusive Dedalo® design employs special floating rings into a labyrinth configuration, ensuring exceptional performance, intrinsec safety, and extended lifetime.

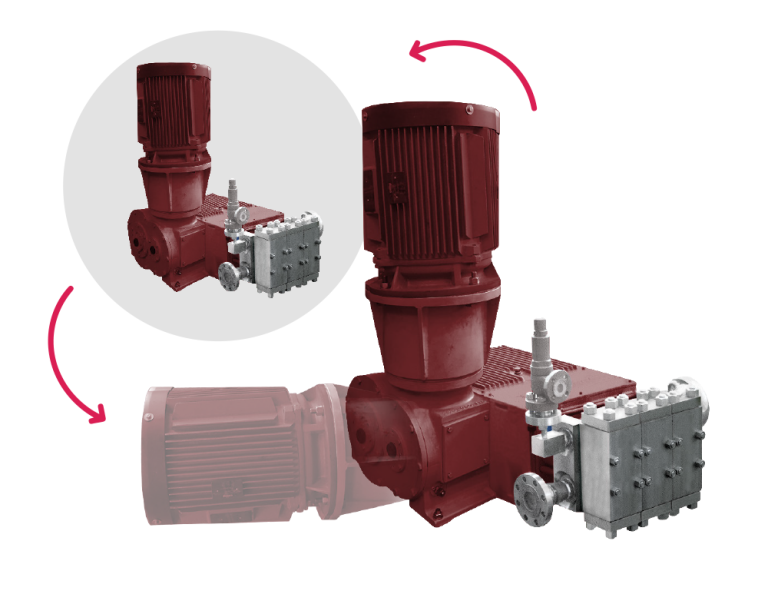

There are no limitations to the possible arrangements of a Peroni Pompe pumping unit! Tailored solutions can be deployed for particular needs, eg. limited space, particular geometry, stringent specs.

Peroni Pompe's innovative Delfi system represents the first condition monitoring tool in the world for process plunger pumps. It can be installed in any environment, including ATEX zones, and in any location, from an urban process plant to an unmanned offshore platform. Its sophisticated algorithms can detect early signs of impending failures, aiding in the prevention of expensive shutdowns. Delfi can be operated both locally (offline), and remotely (online) with optional direct support from Peroni after sales technicians.

Reciprocating Pumps

High-pressure pumps utilizing reciprocating motion of plungers and one-way check valves to transfer fluid, generating high pressure downstream of the pump.

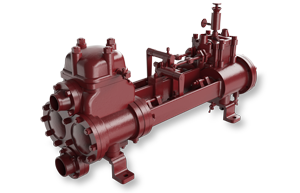

Reciprocating pumps propelled by steam pressure, typically employed in high-capacity applications where electric power isn't readily accessible.

Multi-cylinder pumps utilizing a flexible double diaphragm between the plungers and the process fluid, completely preventing leaks into the atmosphere.

Precision pumps designed to convey precise volumes of liquid over specified time intervals, ensuring accurate, repeatable, and adjustable flow rates.

PRODUCTS

Via Tacito, 4 - 20094

Corsico (Milan) Italy

T. +39 02 48940.1

F. +39 02 48910287

marketing@peronipompe.it